Argonne studies 3D-printed steels for next-gen nuclear reactors

Source: interestingengineering

Author: @IntEngineering

Published: 9/25/2025

To read the full content, please visit the original article.

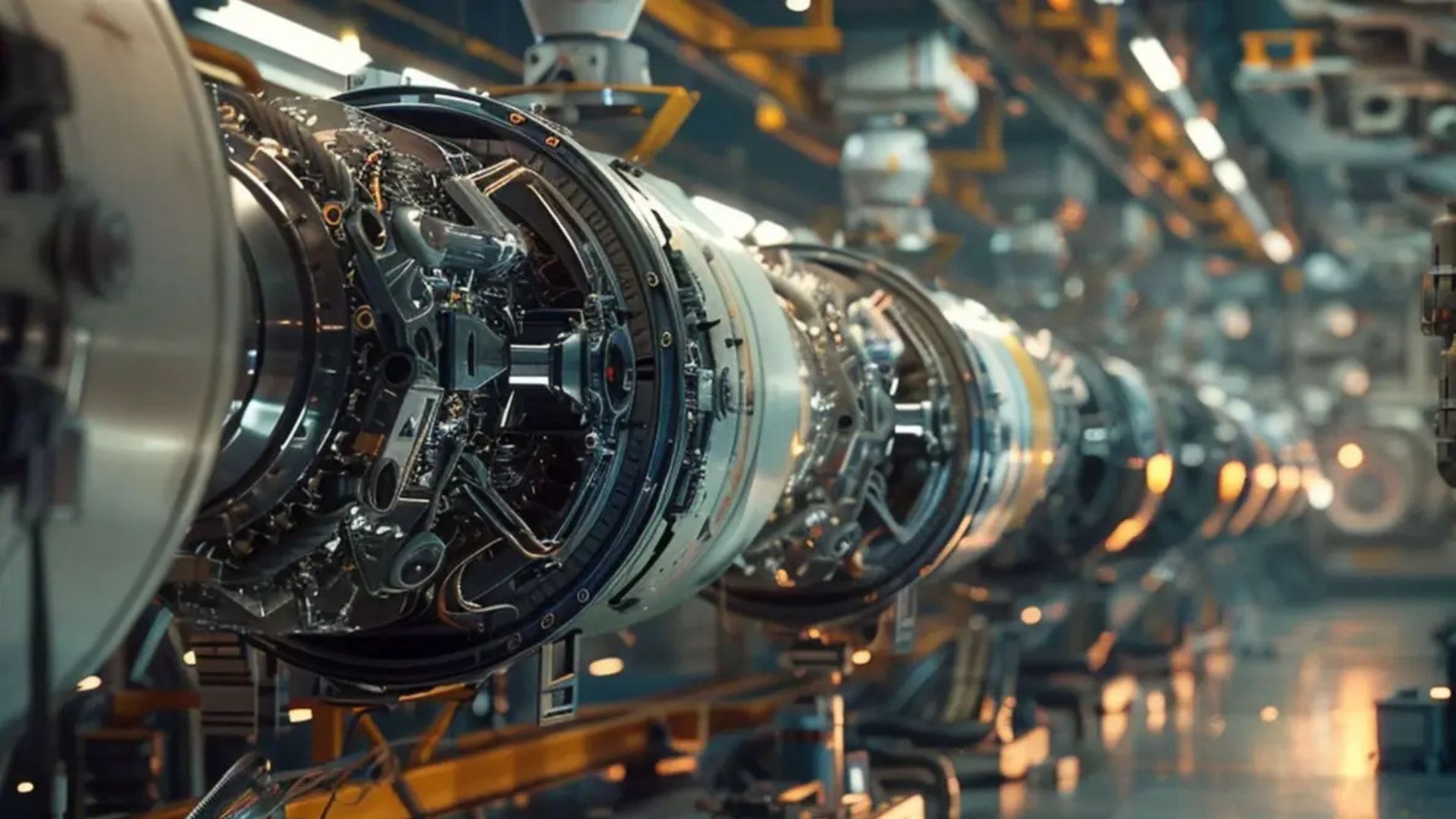

Read original articleResearchers at the US Department of Energy’s Argonne National Laboratory have conducted studies on 3D-printed stainless steels to support the development of next-generation nuclear reactor components. Using laser powder bed fusion (LPBF), an additive manufacturing technique, they produced samples of two key alloys: 316H, a conventional stainless steel used in reactors, and Alloy 709 (A709), a newer alloy designed for advanced nuclear applications. The LPBF process creates unique microstructural features due to rapid heating and cooling, including numerous dislocations that can both strengthen the steel and increase its susceptibility to fracture. Heat treatments are applied to relieve stress by allowing atomic rearrangement, but some dislocations may be retained to enhance performance.

The studies revealed significant differences between 3D-printed and conventionally wrought steels, particularly in how the printed materials respond to heat treatments. For 316H, experiments using advanced microscopy and in situ X-ray diffraction showed that nano oxides—common defects in 3D-printed

Tags

materials3D-printingadditive-manufacturingstainless-steelnuclear-reactorsheat-treatmentlaser-powder-bed-fusion