Boeing 3D-prints solar arrays, cutting satellite build time by 50%

Source: interestingengineering

Author: @IntEngineering

Published: 9/11/2025

To read the full content, please visit the original article.

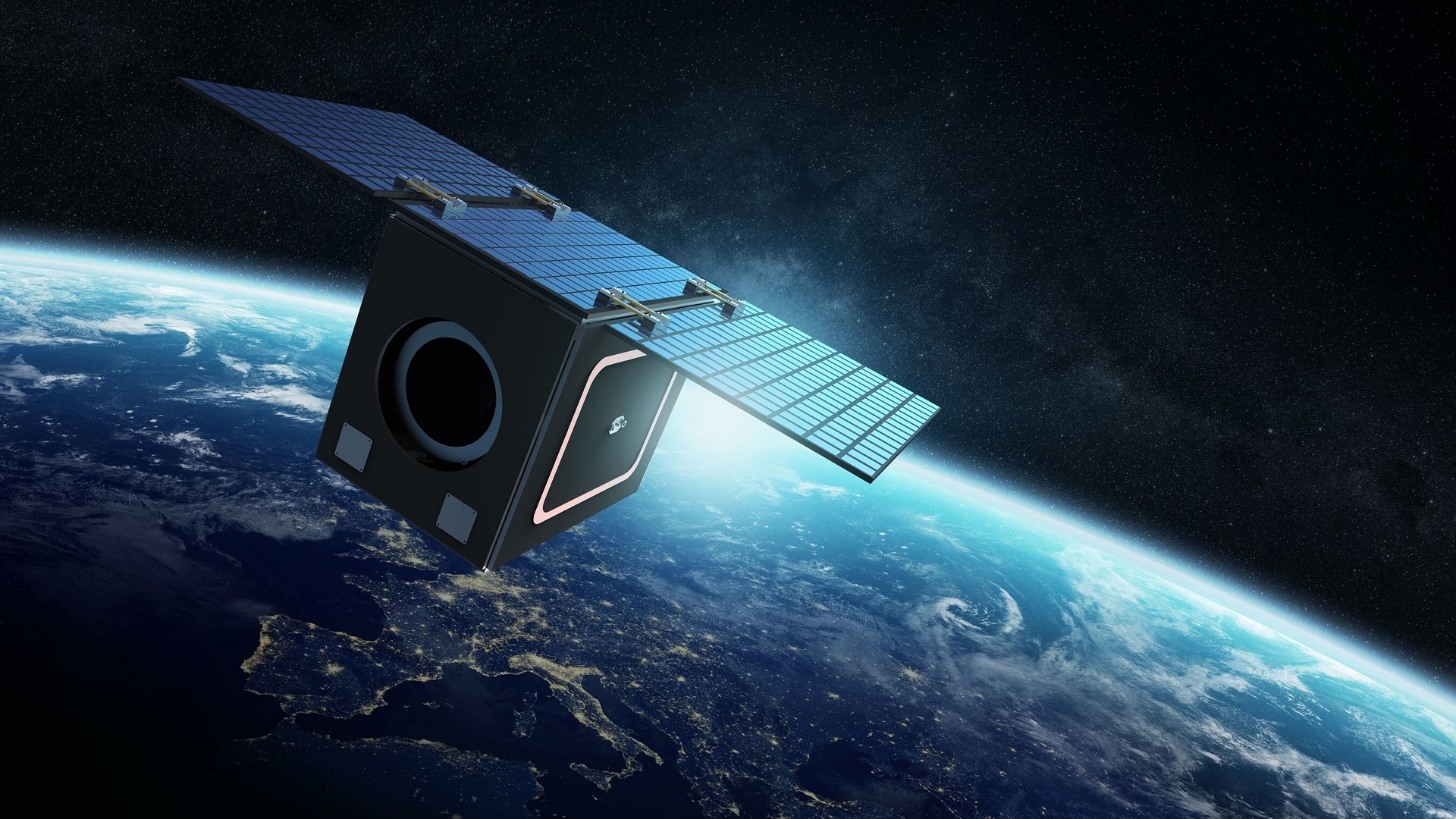

Read original articleBoeing has introduced 3D-printed solar array substrates that significantly reduce satellite production time by up to 50%, cutting composite build times by as much as six months on typical solar array wing programs. This innovation integrates features such as harness paths and attachment points directly into a single rigid panel, eliminating numerous separate parts and complex bonding steps. The arrays, which incorporate Spectrolab’s high-efficiency solar cells and are set to fly on small satellites built by Millennium Space Systems, are currently undergoing Boeing’s qualification process with market availability targeted for 2026.

The new additive manufacturing approach enables parallel production processes, allowing solar arrays to be assembled concurrently with solar cell fabrication, thereby reducing lead times and supporting higher-rate production. Boeing’s use of robot-assisted assembly and automated inspection further enhances consistency and speed. This scalable technology is designed for a range of spacecraft, from small satellites to larger platforms like Boeing’s 702-class spacecraft. Boeing has already integrated over 150,000 3D-printed

Tags

energysolar-energy3D-printingaerospacesatellite-technologyadditive-manufacturingBoeing