Data-driven maintenance is changing factory economics

Source: interestingengineering

Author: @IntEngineering

Published: 9/16/2025

To read the full content, please visit the original article.

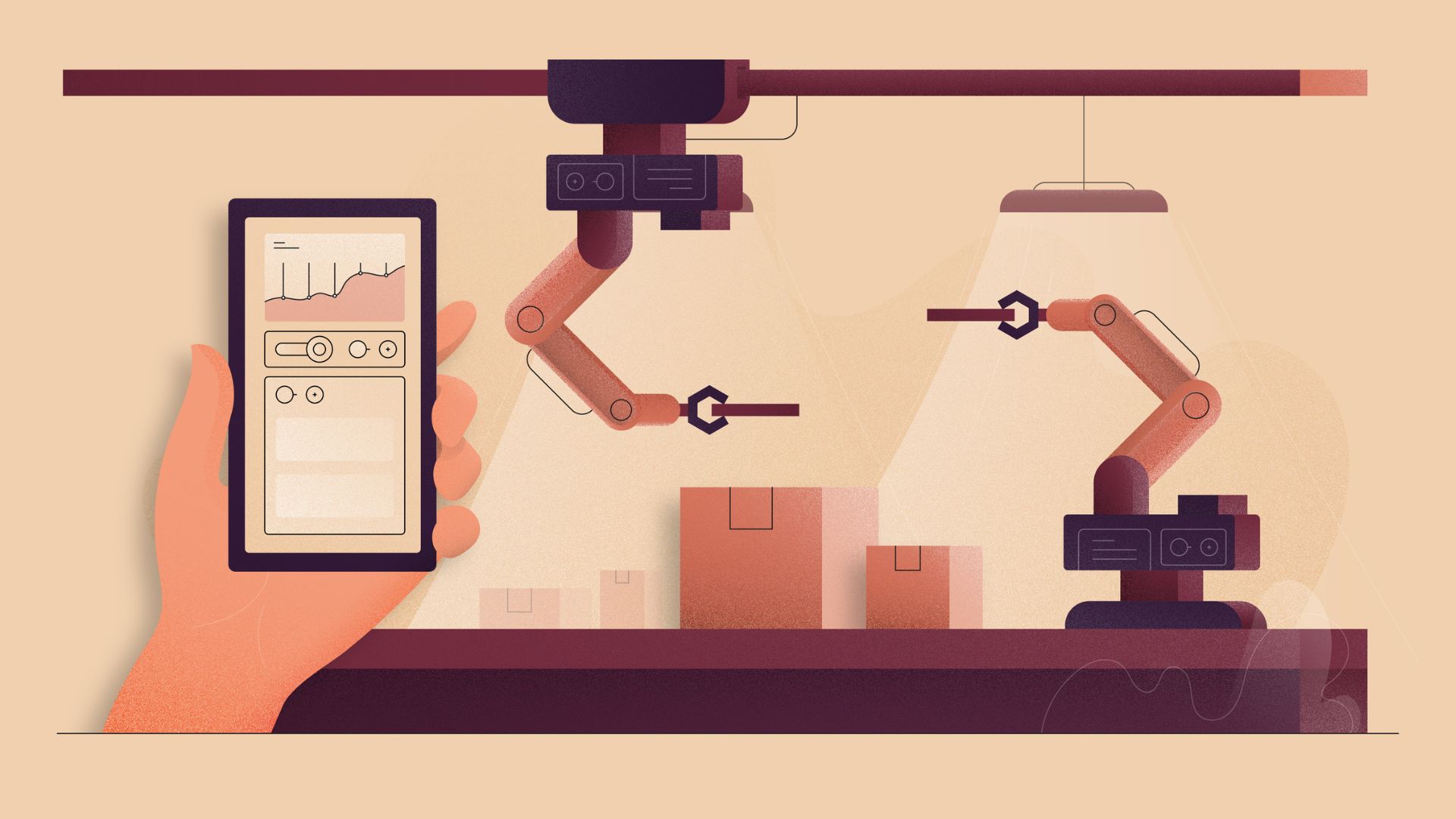

Read original articleThe article highlights how data-driven predictive maintenance is revolutionizing factory economics by significantly reducing unplanned downtime, which can cost factories millions of dollars annually. Traditional reactive “break-and-fix” approaches are being replaced by smart strategies that leverage IoT sensors and AI to detect equipment faults weeks before failures occur. Studies from the US Department of Energy and industry surveys show that mature predictive maintenance programs can yield a 10× return on investment and reduce downtime by 35–45 percent. Additionally, companies adopting these technologies report substantial cost savings, fewer breakdowns, and extended equipment life, with Deloitte and IBM data supporting reductions of up to 70 percent in breakdowns and 25–30 percent in maintenance costs.

The article explains the anatomy of a smart factory’s sensor system, where multiple IoT sensors continuously monitor parameters such as vibration, temperature, and fluid levels. These sensors feed data into edge computing nodes and cloud platforms, where AI algorithms analyze deviations from normal operating baselines to identify early signs of wear

Tags

IoTpredictive-maintenancesmart-factoryAIindustrial-sensorsedge-computingenergy-efficiency