Flash heating extracts rare earths from e-waste with 90% yield

Source: interestingengineering

Author: @IntEngineering

Published: 9/30/2025

To read the full content, please visit the original article.

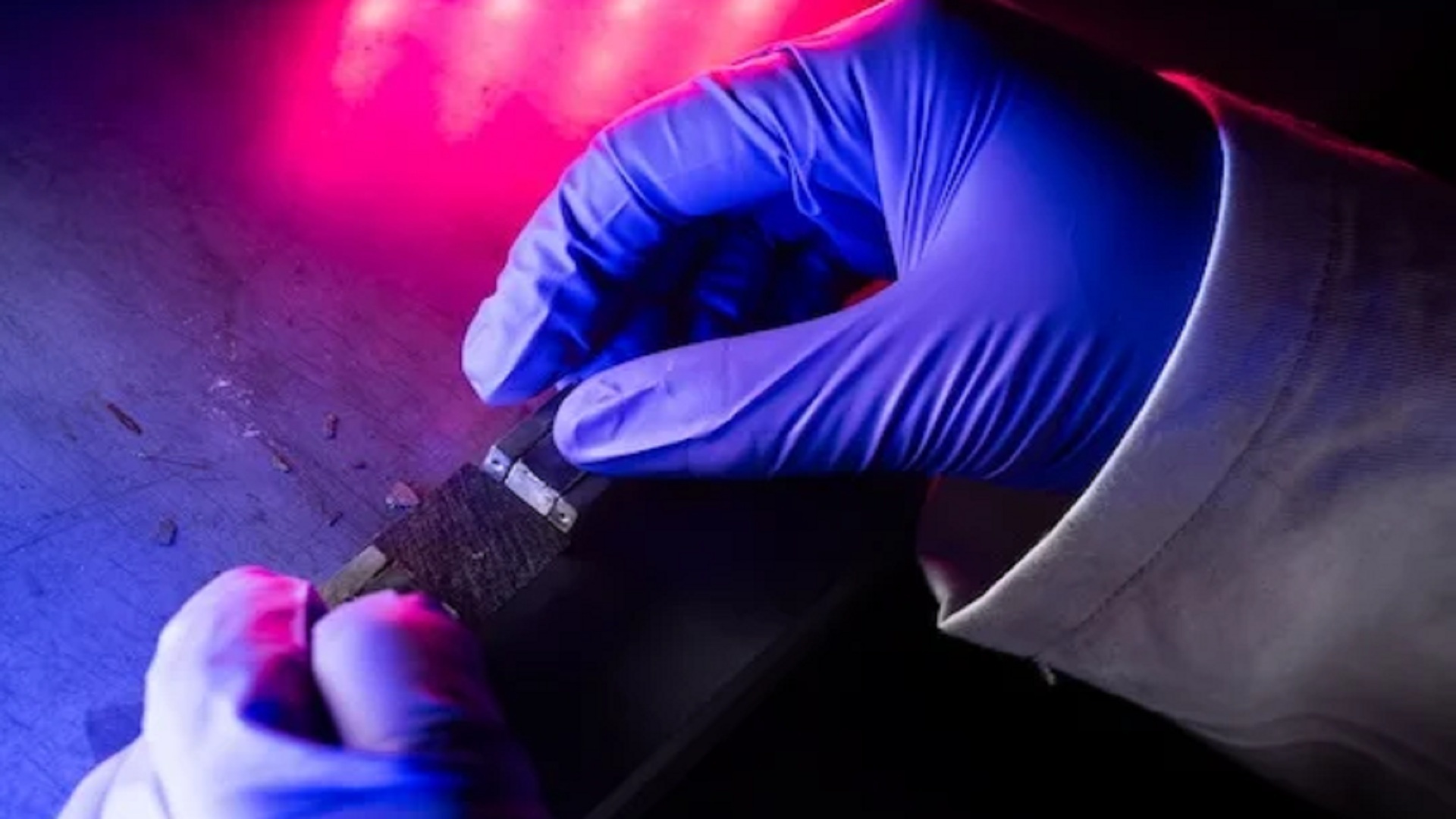

Read original articleResearchers at Rice University, led by James Tour and Shichen Xu, have developed an ultrafast flash Joule heating (FJH) method combined with chlorine gas to recover rare earth elements (REEs) from discarded magnets with over 90% yield and purity. This innovative technique rapidly heats materials to thousands of degrees within milliseconds, causing non-REE metals like iron and cobalt to chlorinate and vaporize first, leaving behind solid REE oxides. Unlike traditional recycling methods, which are energy-intensive and produce toxic waste, this process requires no water or acids, significantly reducing environmental impact.

Life cycle assessments and techno-economic analyses demonstrate that this method cuts energy use by 87%, greenhouse gas emissions by 84%, and operating costs by 54% compared to conventional hydrometallurgical recycling. The rapid and clean recovery process enables the potential deployment of localized recycling units near e-waste collection points, minimizing shipping costs and environmental footprint. Rice University has licensed the technology to Flash Metals USA

Tags

energymaterialsrare-earth-elementsrecyclingflash-Joule-heatingsustainable-processingelectronic-waste