Japan's nuclear reactor robot inspector boosts power plant safety

Source: interestingengineering

Author: @IntEngineering

Published: 10/9/2025

To read the full content, please visit the original article.

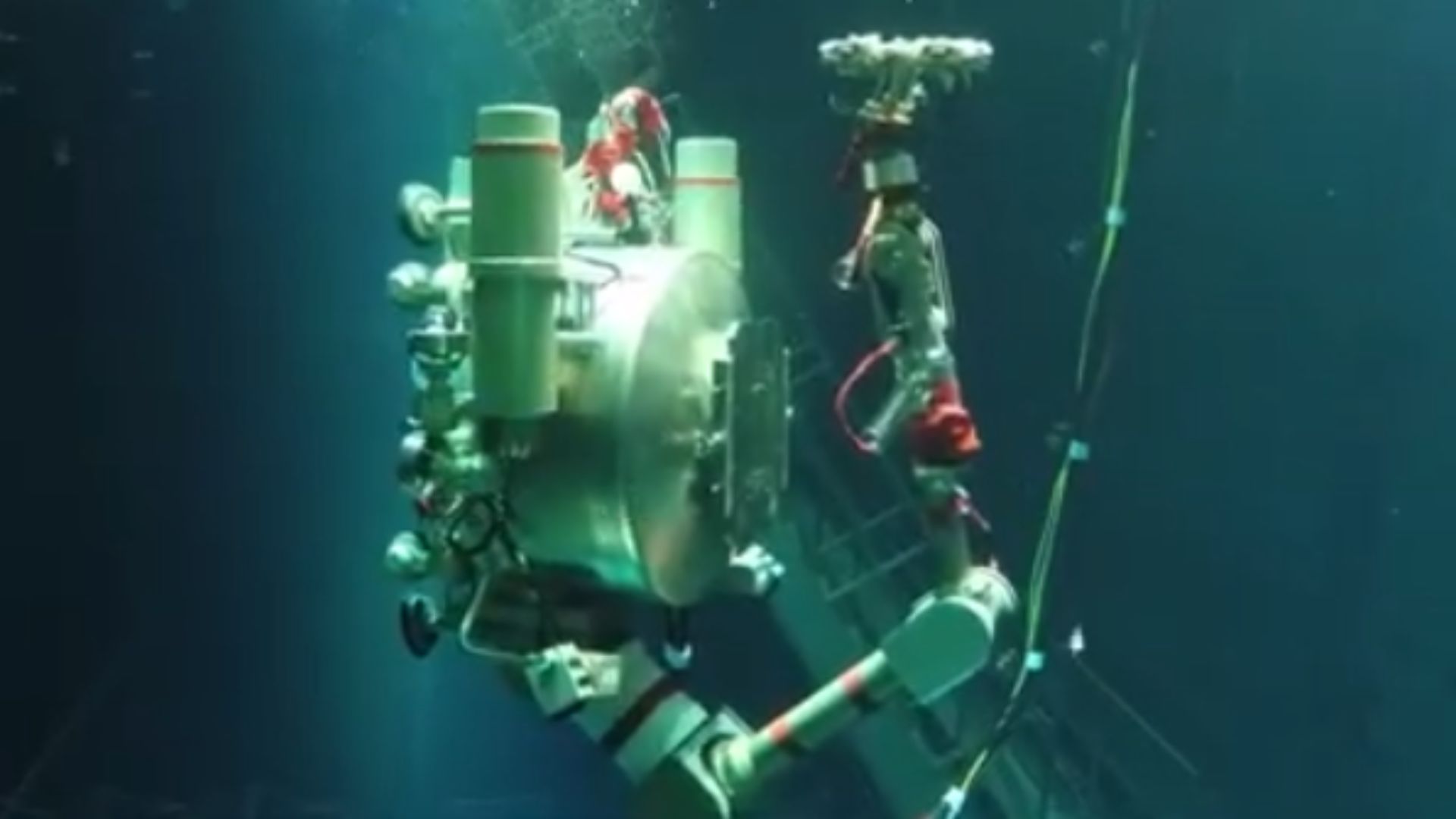

Read original articleJapan’s Mitsubishi Heavy Industries (MHI) Group has developed the A-UT, an autonomous underwater inspection robot designed to perform non-destructive inspections inside nuclear reactor vessels. These vessels operate under extreme conditions of high radiation, temperature, and pressure, making human inspections infeasible. The A-UT, equipped with a seven-axis robotic arm and ultrasonic sensors, remotely navigates the reactor’s interior by swimming and adhering to walls using vacuum pads. It can scan weld lines at a speed of 200 millimeters per second, significantly accelerating inspection times. The robot has been in use since 1995 at pressurized water reactor plants across Japan, with over 50 deployments, and can operate up to 20 meters underwater.

The A-UT robot plays a critical role in maintaining nuclear plant safety by enabling detailed and timely inspections that reduce operational risks and support uninterrupted power generation. Its long-standing service earned it the top Maintenance Heritage certification from the Japan Society of Maintenology, recognizing it as a significant cultural

Tags

robotnuclear-powerautonomous-inspectionunderwater-robotMitsubishi-Heavy-Industriesenergy-safetyultrasonic-testing