New study by US engineers improves strength prediction in 3D printing

Source: interestingengineering

Author: @IntEngineering

Published: 8/2/2025

To read the full content, please visit the original article.

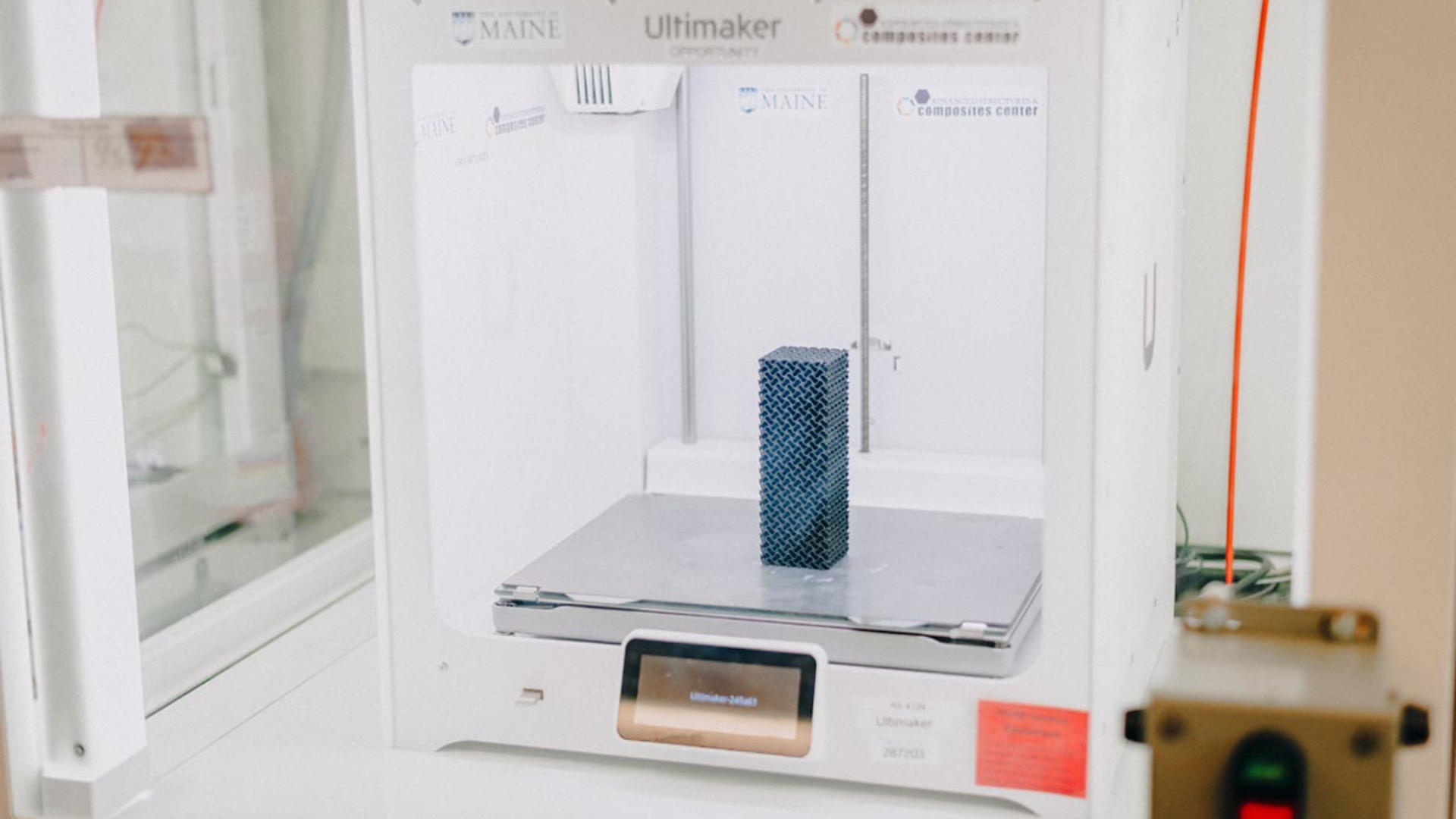

Read original articleA research team at the University of Maine, led by engineers Philip Bean, Senthil Vel, and Roberto Lopez-Anido, has developed a novel method to improve strength prediction in lightweight 3D-printed parts, focusing on the gyroid infill pattern. This pattern, commonly used in additive manufacturing to reduce weight while maintaining strength, was analyzed through a combination of advanced computer modeling and physical stress testing. The team validated their finite element analysis (FEA) simulations with real-world compression and shear experiments, resulting in semi-empirical equations that enable more convenient and accurate strength predictions for design and optimization purposes.

This approach addresses limitations of traditional analytical methods that struggle with complex internal geometries, providing deeper insights into how gyroid infill distributes stress and contributes to overall structural performance. The improved predictive capability allows engineers to optimize designs by balancing material efficiency and structural integrity, reducing material usage without compromising strength. The breakthrough is expected to benefit industries requiring strong, lightweight components, such as aerospace, automotive, and

Tags

3D-printingadditive-manufacturingmaterials-sciencegyroid-infillstructural-strengthlightweight-materialsmechanical-engineering