'Self-fixturing’ friction stir welding could soon enter into manufacturing

Source: interestingengineering

Author: @IntEngineering

Published: 9/19/2025

To read the full content, please visit the original article.

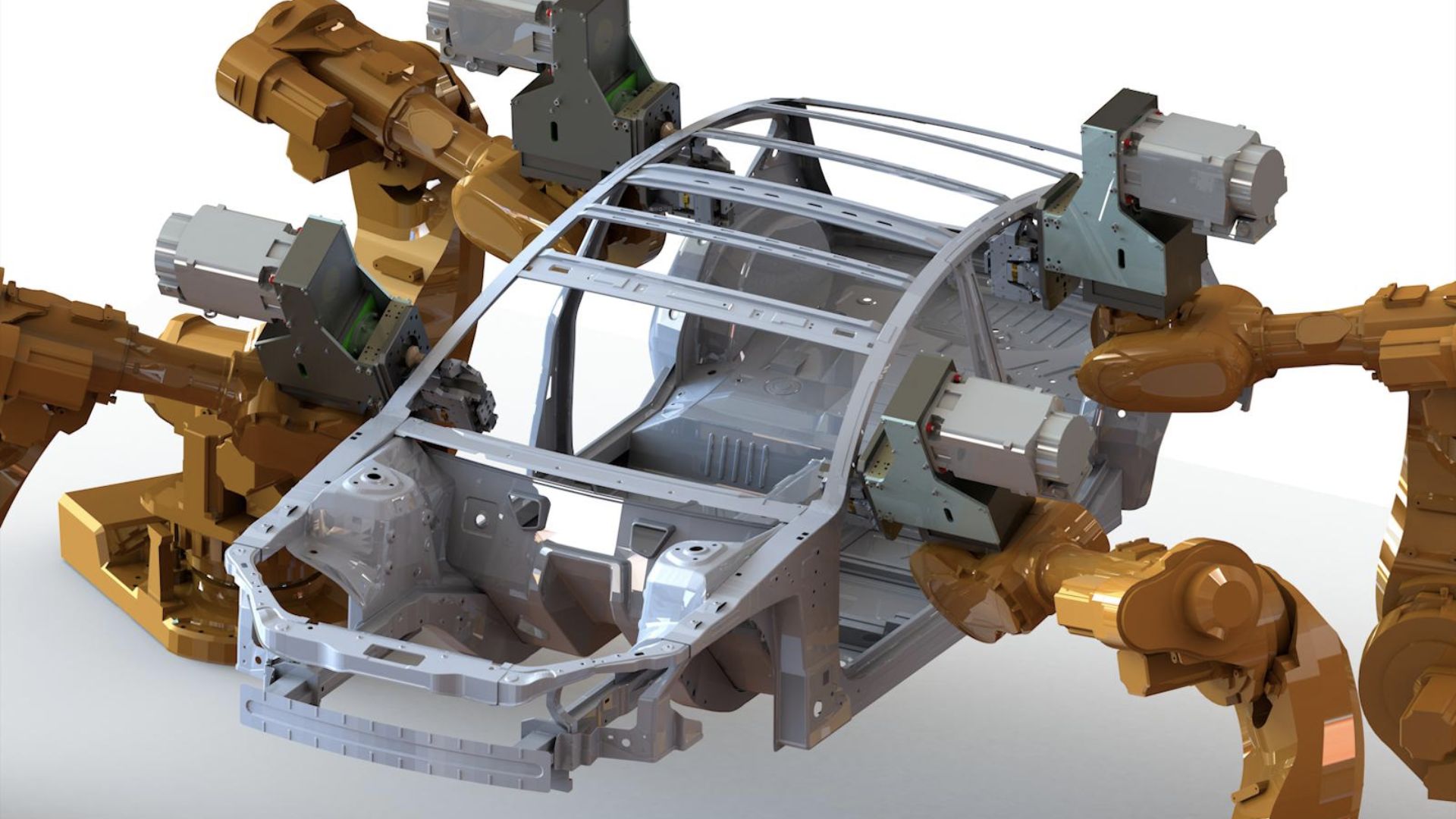

Read original articleA breakthrough at the U.S. Department of Energy’s Pacific Northwest National Laboratory (PNNL) promises to expand the use of friction stir welding (FSW) in manufacturing, particularly on automotive assembly lines. FSW is an energy-efficient welding technique that uses a spinning tool to generate heat and deformation, joining metals without rivets or adhesives. However, its adoption has been limited because the process exerts tremendous force—up to 5,000 pounds—that traditionally requires a rigid anvil underneath the materials to constrain and ensure precise welds. This constraint has made it difficult to apply FSW broadly on assembly lines.

PNNL researchers have developed a novel “self-fixturing” friction stir welding system that integrates both the spinning tool and a miniature backing plate into a robotic arm attachment. This innovation eliminates the need for a separate rigid anvil, allowing the welding tool to be more maneuverable and adaptable to complex parts. The team is also incorporating a hydraulic system that captures the forces generated during welding,

Tags

friction-stir-weldingadvanced-manufacturingrobotic-armsmaterials-scienceenergy-efficiencyautomotive-manufacturingself-fixturing-technology