Soft probes unlock nondestructive testing of micro LED wafers

Source: interestingengineering

Author: @IntEngineering

Published: 7/4/2025

To read the full content, please visit the original article.

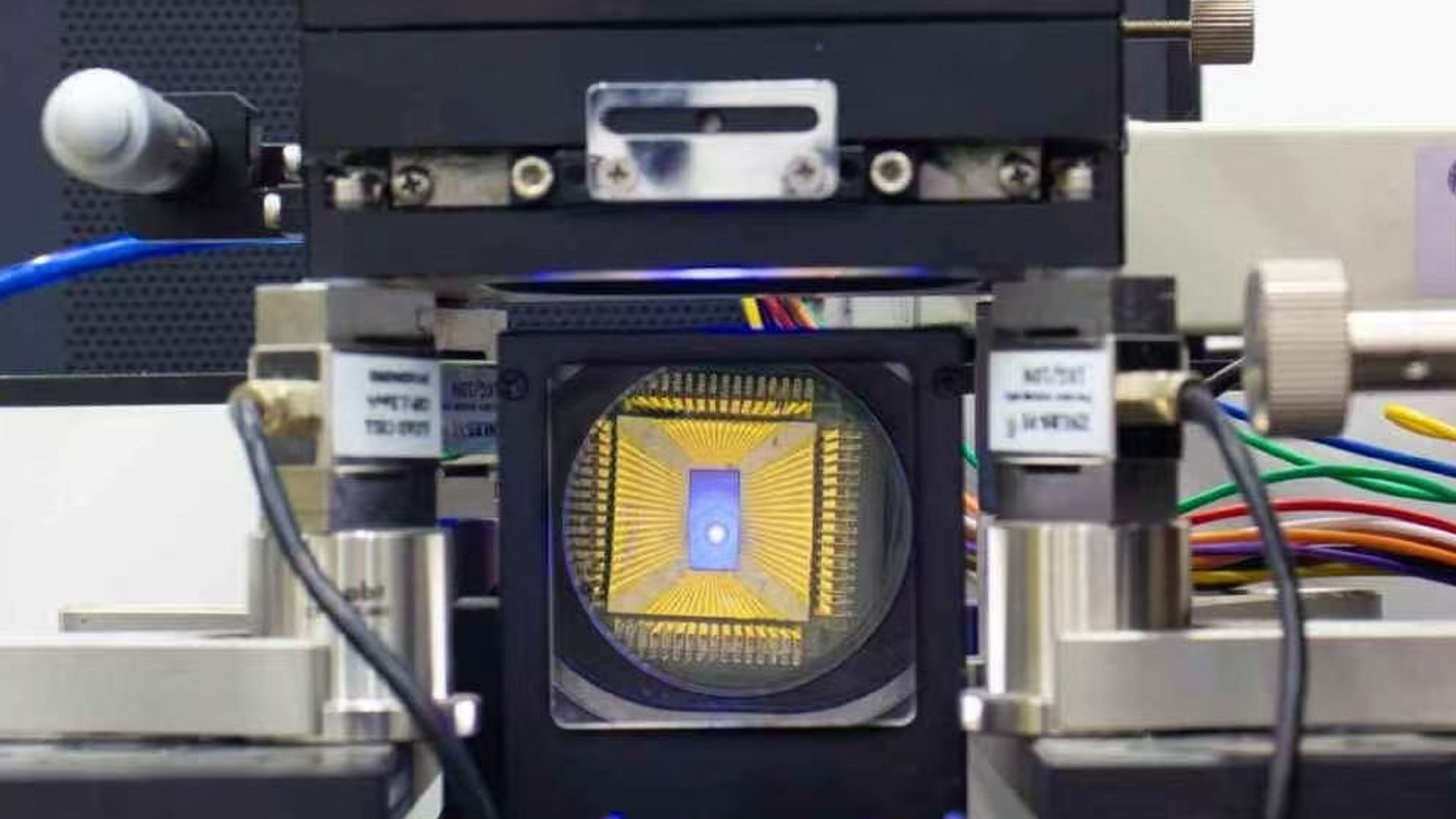

Read original articleResearchers at Tianjin University have developed the world’s first soft probe for non-destructive testing of micro-LED wafers, addressing a critical challenge in the production of next-generation micro-LED displays. Micro-LED technology promises ultra-bright, energy-efficient screens for applications ranging from high-end TVs to flexible wearables, but ensuring high manufacturing yields requires rigorous quality testing. Traditional contact-based probes risk damaging the delicate wafer surfaces, while non-contact methods often lack precision. The new soft-touch system uses a flexible 3D probe array that applies a minimal pressure of just 0.9 MPa—comparable to a gentle breath—significantly reducing the risk of scratches and extending probe lifespan even after one million contact cycles.

This innovation enables high-throughput electrical testing crucial for mass production without compromising wafer integrity, effectively overcoming a major bottleneck in scaling micro-LED manufacturing. Led by Professor Huang Xian, the team’s technology integrates custom measurement systems with the flexible probes, offering a scalable,

Tags

materialsmicro-LEDnon-destructive-testingflexible-probeswafer-fabricationdisplay-technologyquality-control