Stronger next-gen 3D-printed titanium alloy developed for aerospace use

Source: interestingengineering

Author: @IntEngineering

Published: 8/17/2025

To read the full content, please visit the original article.

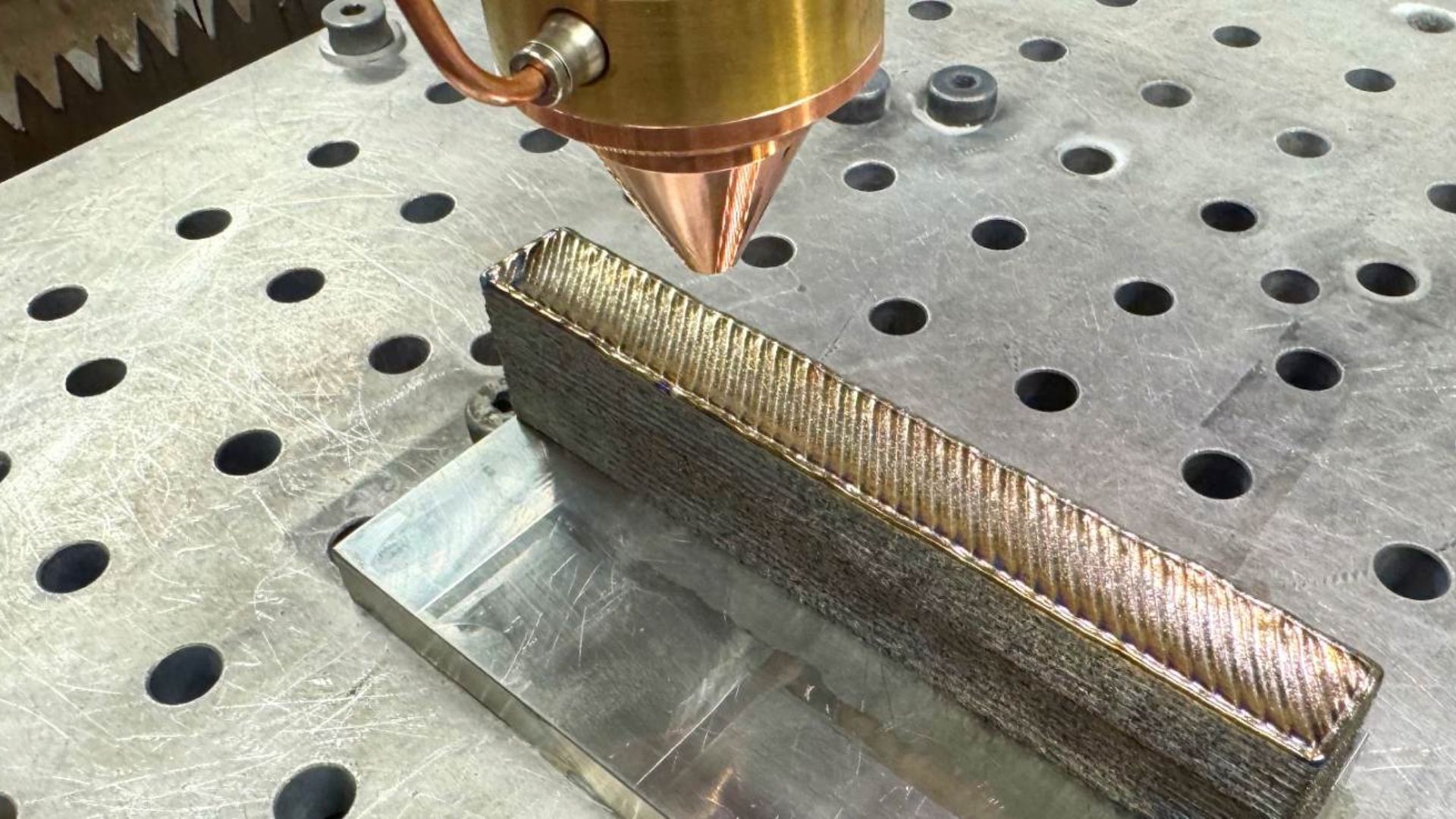

Read original articleEngineers at the Royal Melbourne Institute of Technology (RMIT) have developed a new 3D-printed titanium alloy that is about one-third cheaper and stronger than the current industry standard, such as Ti-6Al-4V. This cost reduction is achieved by replacing the expensive element vanadium with more accessible, lower-cost materials. The new alloy also overcomes a common issue in 3D-printed metals by avoiding the formation of columnar microstructures, resulting in a uniform grain structure that enhances both strength and ductility. These improvements address key challenges that have hindered the widespread adoption of 3D-printed titanium in aerospace and medical device industries.

The research introduces a novel framework for designing metallic alloys tailored specifically for additive manufacturing, moving beyond legacy alloys that limit the potential of 3D printing. The team has produced and tested samples at RMIT’s Advanced Manufacturing Precinct and is now seeking industry partners to help commercialize the alloy. A provisional patent has been filed for the

Tags

3D-printingtitanium-alloymaterials-scienceadditive-manufacturingaerospace-materialsmetal-alloyscost-effective-materials