UK nuclear fusion labs to get 3D boost to build tougher reactor parts

Source: interestingengineering

Author: @IntEngineering

Published: 7/22/2025

To read the full content, please visit the original article.

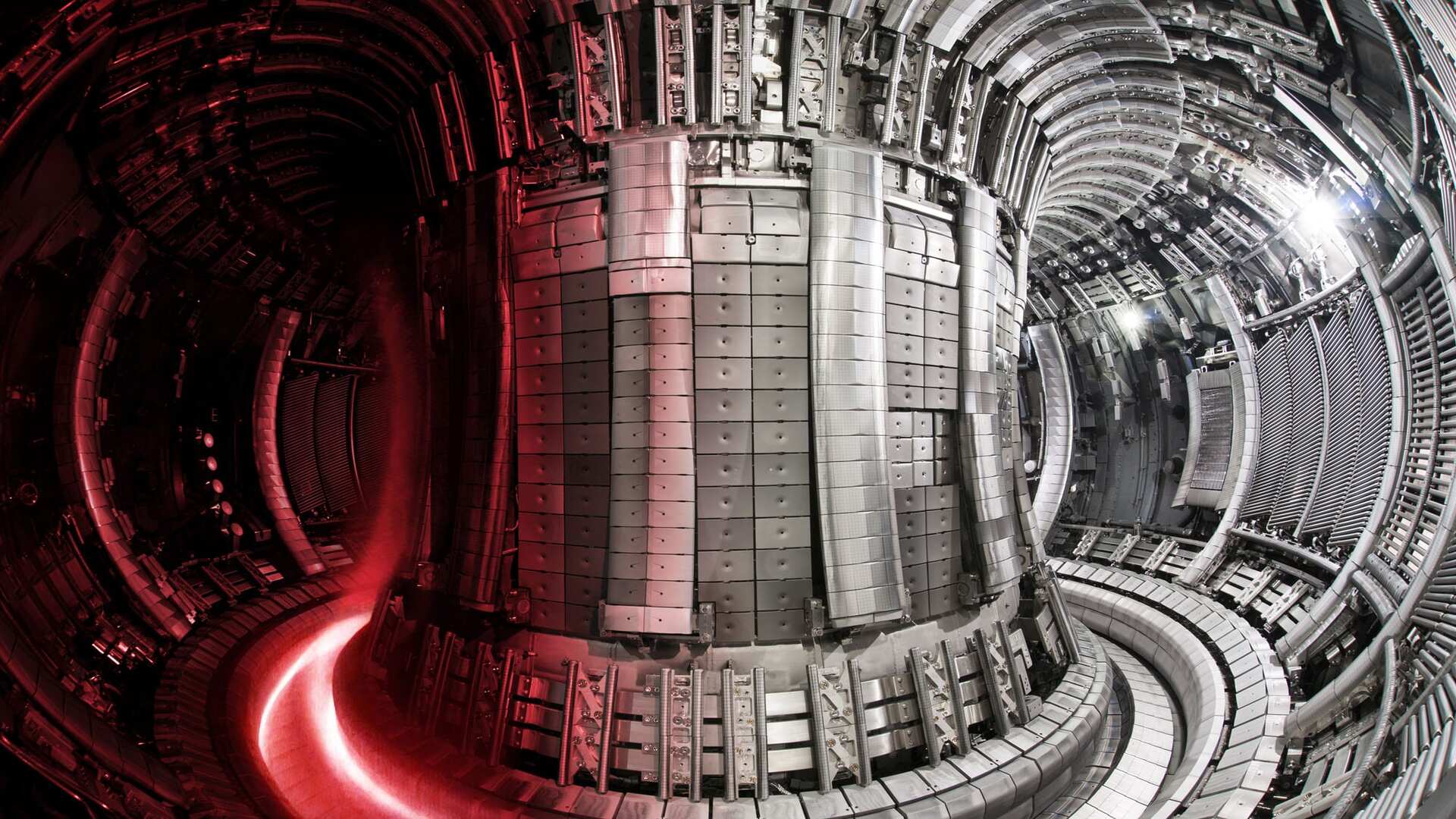

Read original articleThe United Kingdom Atomic Energy Authority (UKAEA) has commissioned two advanced 3D printing machines to produce components for future nuclear fusion reactors capable of withstanding extreme conditions such as high heat, intense neutron radiation, and strong magnetic fields. These machines, housed at the new Central Support Facility, include an electron beam powder bed fusion (E-PBF) system from Freemelt designed to fuse tungsten powder into dense, ultra-tough plasma-facing parts, and a selective laser melting (SLM) machine from Nikon SLM Solutions for fabricating complex geometries and material combinations. Both additive manufacturing methods aim to reduce reliance on traditional fabrication techniques like welding, streamlining production and enhancing precision.

UKAEA emphasizes that additive manufacturing is critical for producing the thousands or millions of specialized components required for commercial fusion power plants, as it allows for intricate designs in small volumes with improved efficiency and potentially lower costs. The dual capability of electron beam and laser-based 3D printing under one roof is a pioneering step for the

Tags

energynuclear-fusion3D-printingadditive-manufacturingtungstenreactor-componentsmaterials-engineering