US creates super metal foam that survives 1.3 million stress cycles

Source: interestingengineering

Author: @IntEngineering

Published: 10/8/2025

To read the full content, please visit the original article.

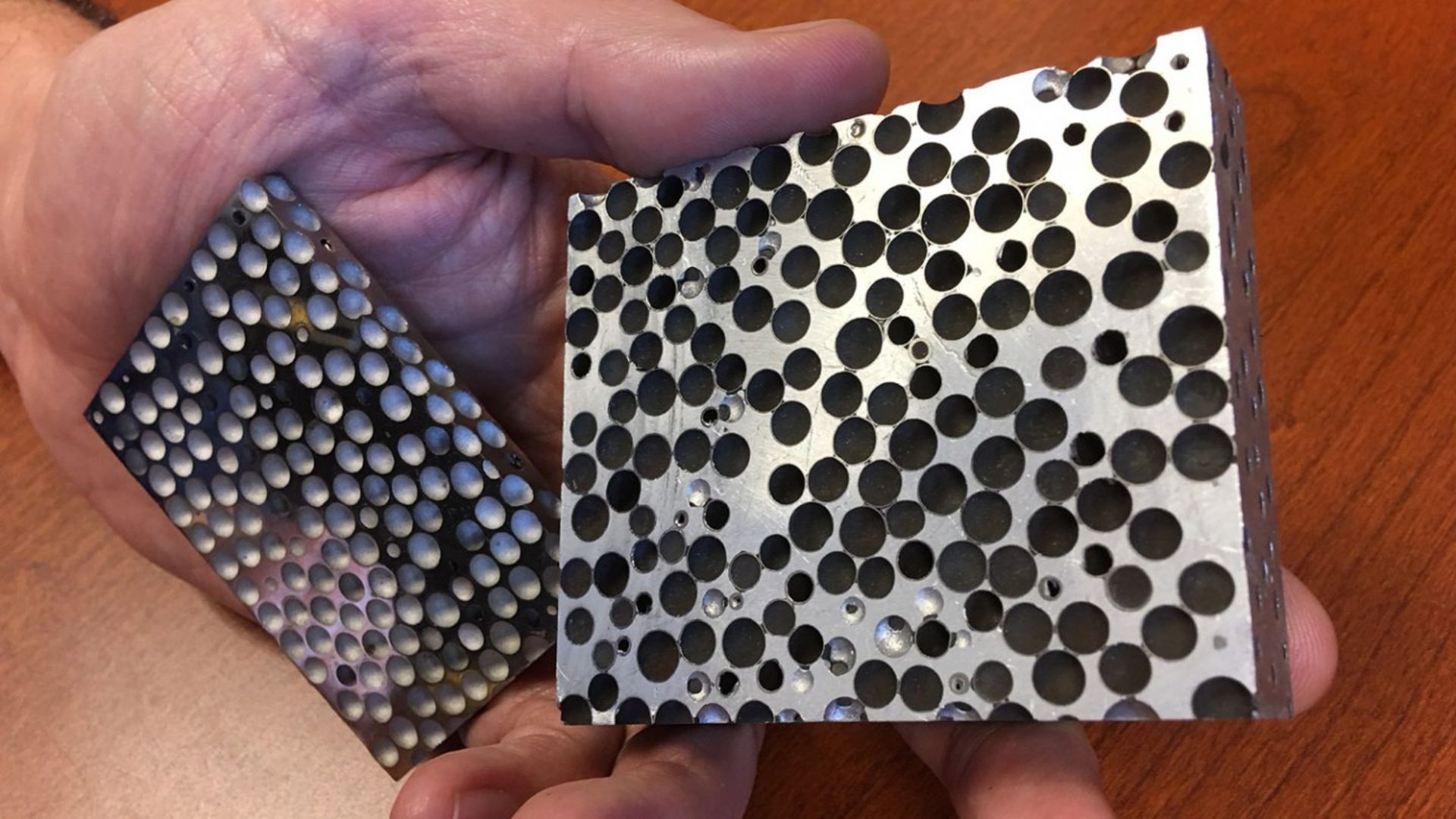

Read original articleResearchers at North Carolina State University have developed a novel Composite Metal Foam (CMF) that combines lightness with exceptional strength and thermal resistance, making it highly suitable for demanding applications such as automotive engines, jet parts, and nuclear reactor components. CMF is composed of hollow metal spheres (e.g., stainless steel or nickel) embedded within a solid metal matrix, resulting in a material that absorbs crushing forces effectively while providing superior insulation against extreme heat compared to conventional metals.

In rigorous testing, the steel-based CMF demonstrated outstanding fatigue resistance, enduring over 1.3 million compression-compression stress cycles at temperatures up to 752°F (400°C) and more than 1.2 million cycles at 1,112°F (600°C) without failure. These results are particularly notable given that the fatigue life of solid stainless steel typically decreases significantly at elevated temperatures. The research highlights CMF’s potential to maintain structural integrity under prolonged high-stress and high-temperature conditions, which is critical for safety-sensitive

Tags

materialsmetal-foamcomposite-metal-foamfatigue-resistancehigh-temperature-materialsnuclear-reactor-materialslightweight-strong-materials