US scientists develop real-time defect detection for 3D metal printing

Source: interestingengineering

Author: @IntEngineering

Published: 6/7/2025

To read the full content, please visit the original article.

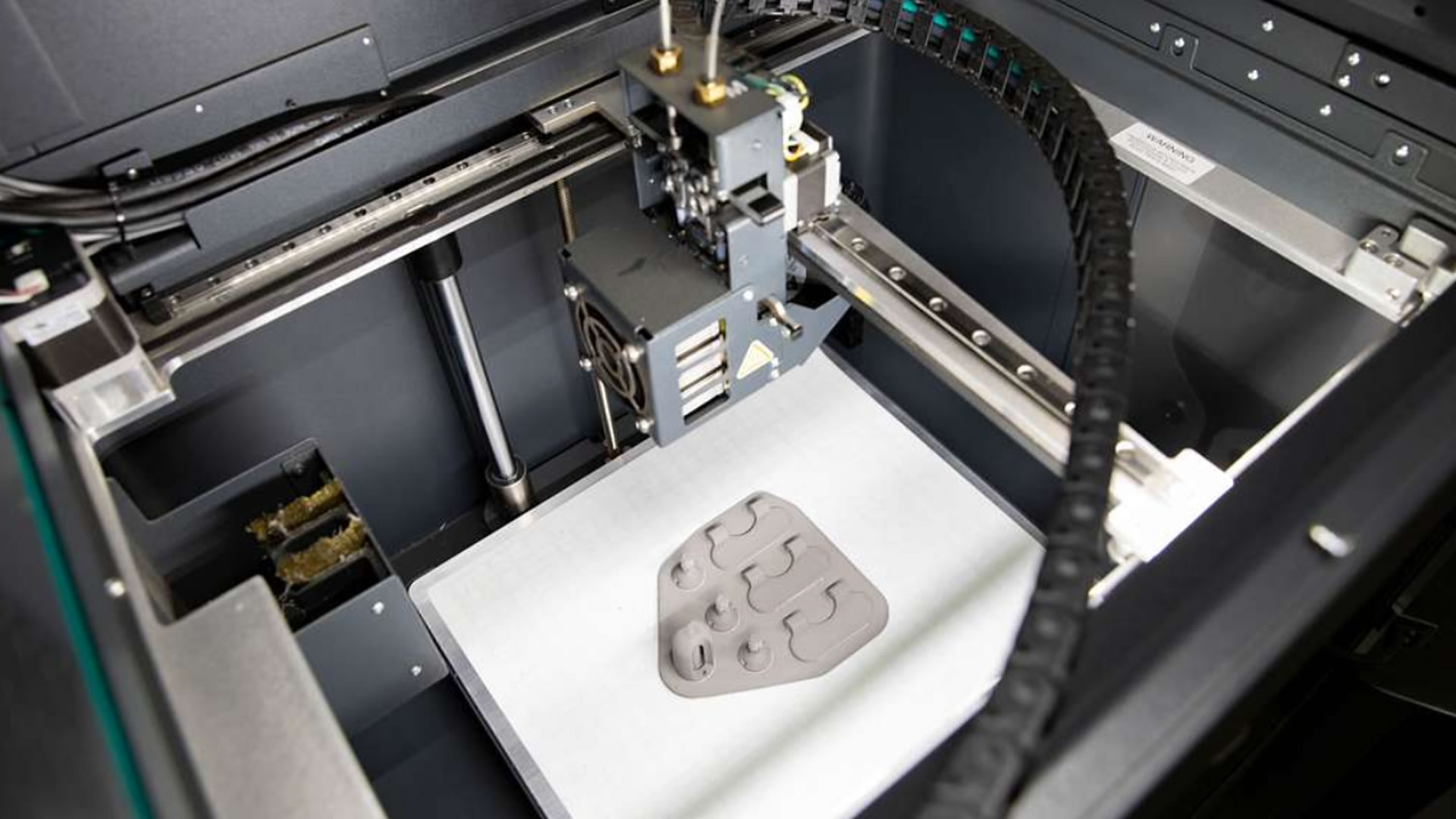

Read original articleScientists from Argonne National Laboratory and the University of Virginia have developed a novel method to detect defects, specifically keyhole pores, in metal parts produced by 3D printing using laser powder bed fusion. Keyhole pores are tiny internal cavities formed when excessive laser energy creates deep, narrow holes that trap gas, compromising the structural integrity and performance of critical components such as aerospace parts and medical implants. The new approach combines thermal imaging, X-ray imaging, and machine learning to predict pore formation in real-time by correlating surface heat patterns with internal defects captured via powerful X-rays.

This method leverages existing thermal cameras already installed on many 3D printers, enabling instant detection of internal flaws without the need for continuous expensive X-ray imaging. The AI model, trained on synchronized thermal and X-ray data, can identify pore formation within milliseconds, allowing for immediate intervention. Researchers envision integrating this technology with automatic correction systems that adjust printing parameters or reprint layers on the fly, thereby improving reliability, reducing waste, and enhancing safety in manufacturing mission-critical metal parts. Future work aims to expand defect detection capabilities and develop repair mechanisms during the additive manufacturing process.

Tags

3D-printingmetal-additive-manufacturingdefect-detectionmachine-learningthermal-imagingX-ray-imagingmaterials-science