US tech gives dead EV batteries 85% power after 900 charge cycles

Source: interestingengineering

Author: @IntEngineering

Published: 7/18/2025

To read the full content, please visit the original article.

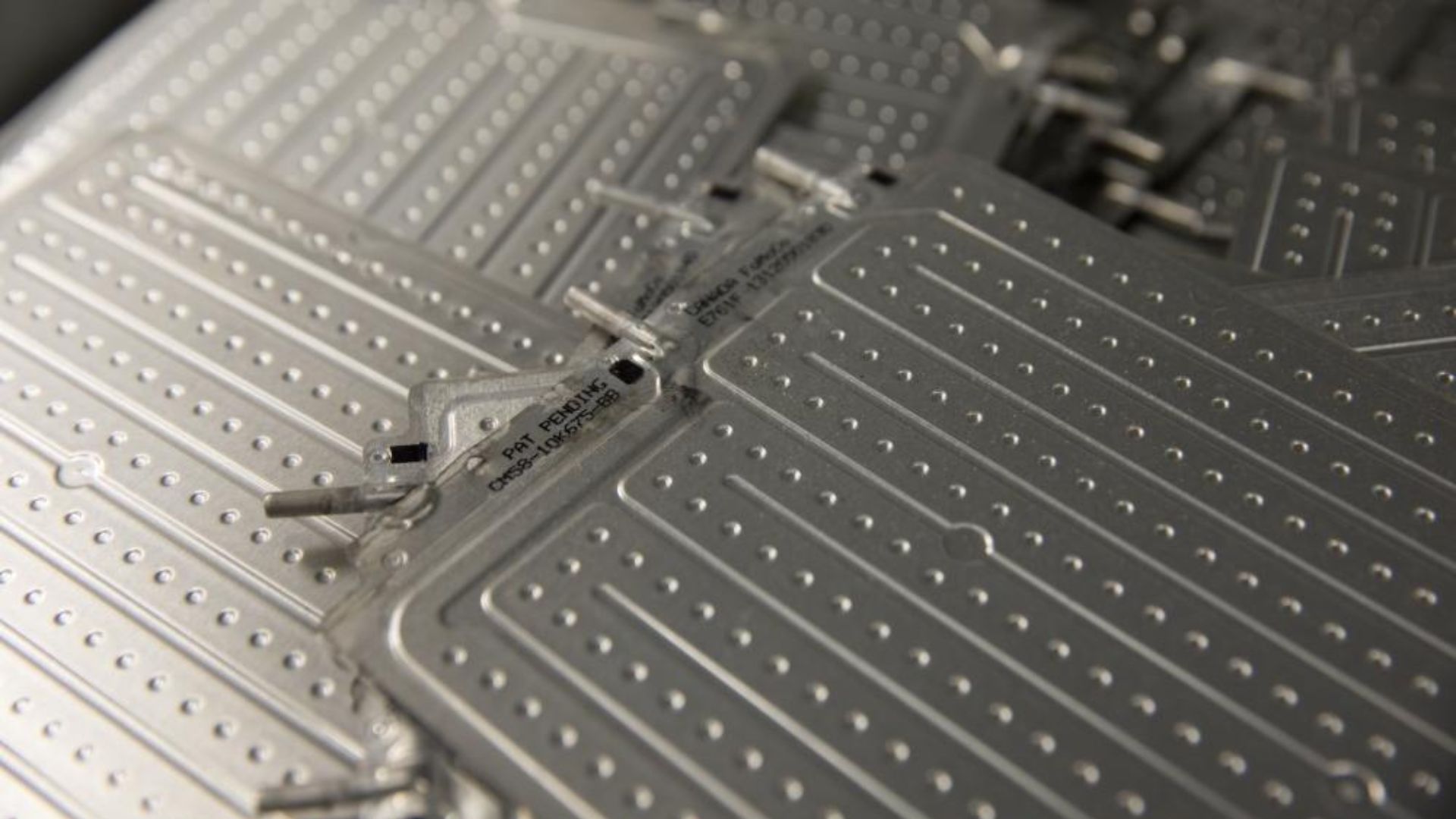

Read original articleResearchers at Worcester Polytechnic Institute (WPI) have developed an environmentally friendly and scalable hydrometallurgical recycling method for lithium-ion batteries, recovering 92 percent of critical metals such as nickel, cobalt, and manganese. This approach converts spent nickel-lean cathode materials into high-quality cathode powder suitable for reuse in batteries. Batteries made from this recycled cathode powder retained 88 percent of their capacity after 500 charge cycles and over 85 percent after 900 cycles, demonstrating strong performance and longevity.

The new method is also energy-efficient, consuming 8.6 percent less energy and reducing carbon emissions by 13.9 percent compared to conventional recycling techniques. This innovation addresses the environmental challenges posed by battery waste and reduces reliance on environmentally damaging mining activities. The research, led by Professor Yan Wang, highlights the potential for creating high-performance batteries from recycled materials at scale, contributing to a more sustainable and resilient battery supply chain essential for supporting renewable energy infrastructure. The findings were published in the journal

Tags

energylithium-ion-batteriesbattery-recyclingrenewable-energysustainable-materialshydrometallurgical-methodelectric-vehicles