World's first 3D-printed rocket part survives cryogenic pressure test

Source: interestingengineering

Author: @IntEngineering

Published: 8/11/2025

To read the full content, please visit the original article.

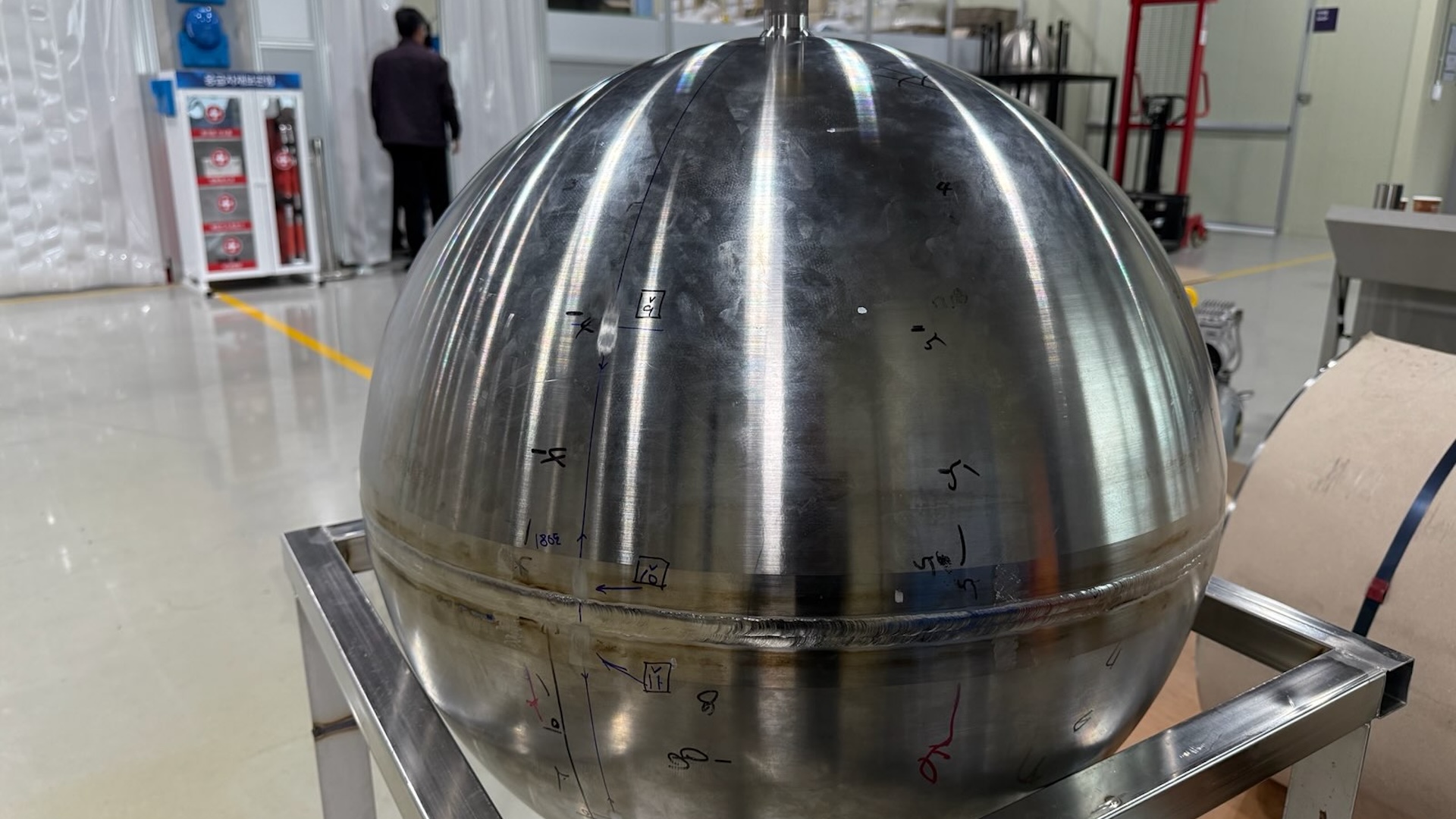

Read original articleA team at the Korea Institute of Industrial Technology (KITECH) has successfully produced the world’s first large titanium rocket fuel tank using 3D printing, specifically the Directed Energy Deposition (DED) process. This 640mm diameter tank, made from Ti64 titanium alloy, was fabricated by melting titanium wire layer-by-layer with a laser, then assembling two hemispheres through machining and welding. The entire manufacturing cycle took only a few weeks, significantly faster than traditional forging methods, which rely on fixed molds and are less adaptable for custom, large-scale parts.

The 3D-printed fuel tank passed a critical cryogenic pressure test conducted by the Korea Aerospace Research Institute (KARI), withstanding pressures of 330 bar at -196°C, conditions simulating spaceflight environments. This milestone demonstrates that large additively manufactured titanium structures can endure extreme temperatures and pressures required for space applications, potentially revolutionizing aerospace manufacturing by reducing costs, lead times, and design constraints. However, further cyclic

Tags

3D-printingtitanium-alloyaerospace-materialscryogenic-pressure-testadditive-manufacturingDirected-Energy-Depositionspace-fuel-tank